Farming Practices

How we do things at Shady Hill.

How you raise food DOES make a difference in the taste and experience.

Pasture-Raised & Non-GMO Chicken

Since we have limited land, we raise small flocks of chickens at a time to ensure the soil health is maintained and the chickens always have fresh grass. We raise chickens from April to October to beat the cold season since they are always outside. Each flock is about 50 chickens, and our homestead keeps at least 20 per flock to feed our family for the year.

Chris built a “chicken tractor” that provides shelter and protects our flocks at night. With plenty of sunshine, air ventilation, and airflow, our chickens stay active and happy. They remain inside the chicken tractor and we pick it up and move it every day to give them fresh grass to be on. We do like to open the door and give them the option to roam, but unless feed is out there, we only see a handful make their way outside the structure due to their prey instincts. Around the chicken tractor, there is a solar-powered, electric fence to protect the flock from predators that may try to get inside the structure at night. In addition to what they find in the grass, we feed a nonGMO corn and soy feed from Sunrise Farms so they have a nutritious diet to grow. Non-GMO means the corn and soy that are consumed from this feed are not genetically modified.

After working at a larger chicken company, Ashley has grown to appreciate quality feed and chose to pasture-raise smaller flock sizes to maintain flock health and use these practices to learn more about the regeneration of our environment. Who doesn’t love seeing clean chickens roaming outside with plenty of space to move?! It gives us more peace of mind about the meat we are choosing to eat. People don’t realize that when chickens are stressed or limited, the growth pattern and meat are affected. We focus on enrichment and outdoor life to aid us in raising a happy bird. They are providing nourishment to us, so it’s the least we can do.

In the distance is the chicken tractor. You can see a path where the grass is pecked down. This is the path the tractor followed as we pulled it. Moving it daily allows the chickens to have a place to scratch and peck fresh ground for a dust bath.

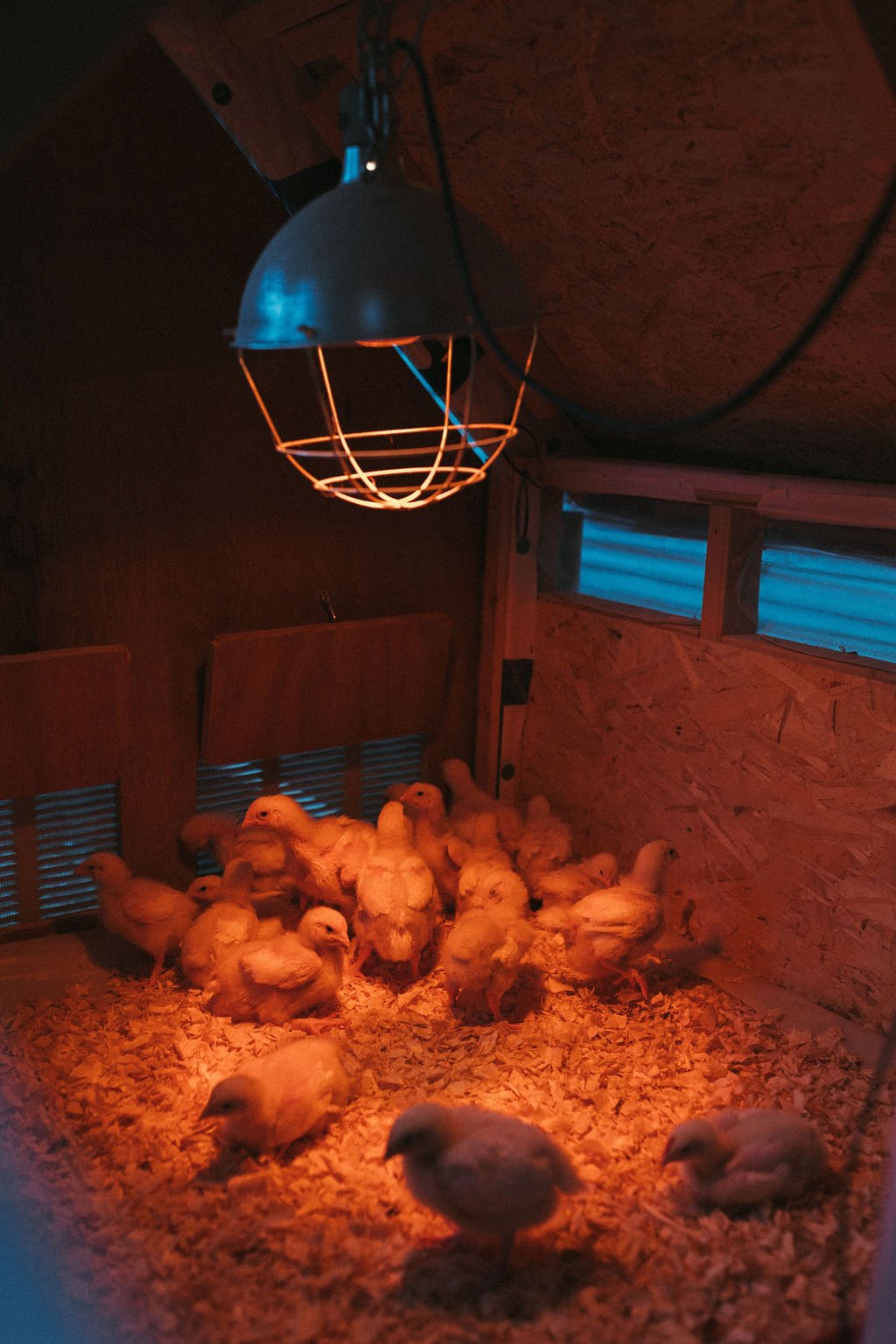

Chicks are in a brooder (mini chicken coop) for 21-28 days. This gives them the time to build strength and feathers that will protect them outdoors. With warmer temps, we let them outside during the warmth of the day to become accustomed to being outdoors after 1.5 weeks.

Chris built this structure with plenty of head space to walk in and tend to the flock and with plenty of room for the chickens to stretch up and not feel limited. Traditional tractors are lower to the ground. With all this room outdoors, our chickens stay clean from poop.

Fresh Cut Flowers

You may see weeds, but you won’t see chemicals. Caterpillars and weeds are annoying, but we are committed to not spraying harmful chemicals on our plants; this is also the landowner’s wish. In 2023, we tried using an organic pesticide and we might as well have used water. We invest in quality compost and fertilizer that will maintain plant growth and help us control pests. If pests are an issue, we will use soapy water and introduce natural predators to our field. Our flowers are grown at Tim and Sandy’s farm, just 7 minutes from our homestead.

We install drip lines to be efficient with our well water being used for the plants. Wildflowers and pollinator plants are planted around our crop to support pollination and our dear pollinators.

Chicken Processing

Often, people don’t like to think about how their food truly gets from farm to table. We believe in being 100% transparent so you are 100% confident that we have done all we can to raise nourishing food for your family that also nourished the land.

Our chicken is raised on our homestead, tended to by us (Chris and Ashley…and the occasional proud Grandpa Bob), and then processed by our hands. Our product is only ever in our care before it gets to your table. We process early in the morning to ensure a cool temperature while we work. Throughout the whole process, we wear gloves and keep things clean. We stay near our home so we have running water to wash things down as we go. After Chris and Ashley pray over the flock, he starts dispatching chickens while Ashley focuses on dressing the chickens to cool them down and prepare them for packaging. Our chickens are placed in a spot where they cannot see the rest of the flock being processed. We also use humane practices to keep them calm throughout the process. This ensures the meat won’t tighten up and be tough.

We use shrink wrap and zip ties to package our final product. We always add the weight product label so you know when it was processed and frozen, and the weight of the chicken was right before it was packaged. We have a permit from the Virginia Dept. of Consumer Services to process the chickens we raise. This is displayed via a “PL” code on your chicken; this is the law.

Your Reviews